This activity consisted of laboratory tests of steel production, with a view to the elaboration of low carbon stainless steels (decarburized) and low S and / or P carbon steels (desulfurized and / or dephosphorated). The decarburization and desulfurization / dephosphorisation processes were tested by reagent addition systems (argon / oxygen in the case of decarburization and reagent additives to be tested in the other case). The results were evaluated in terms of the mechanical properties of the steels, and the results optimized for the transition to the industrial / pilot research phase (activity 5).

The experimental procedure consisted of the fusion of the raw materials, including the addition of ferroalloys and composition adjustment elements, focusing on one of the types of stainless steels and one of the carbon steels previously selected in activity 1. Chemical composition was controlled by spectrometer analysis, performed internally at Ferespe, Lda., except for the subcontracted oxygen analysis. In the case of the decarburization of stainless steels, a refractory lined steel lance was developed internally at Ferespe, Lda., With the support of argon-oxygen mixtures. Since this is not the ideal situation, as it is still a rudimentary system, it has, however, allowed insufflation under sufficient and adequate conditions to evaluate procedures and results. In the case of the addition of powdered materials to treat carbon steels, samples were subcontracted for waste preparation and inflated with the same iron lance system, adapting it with equipment. pneumatic pressurization, including tank. From each test specimens were leaked for preliminary microstructure verification and mechanical testing.

6 alloys were made from each of the following materials:

- Stainless Steel ASTM A995-13Gr6A

- Carbon steel ASTM A352 LCC

In each case, after the total melting of the raw materials, the material was chemically analyzed to determine the necessary correct additions. After adjusting the composition of the elements that could be corrected by additions, the materials were introduced by insufflation (gases or powders) for varying times, and the specimens were collected for characterization after leakage in the spoon. In this case a certain amount of aluminum was always placed in order to guarantee the good deoxidation of the steel, necessary to obtain good internal health of the test pieces.

In the case of stainless steels, after adjusting the chemical composition for the main elements, a 10% by volume oxygen argon mixture was purchased from the bottle.

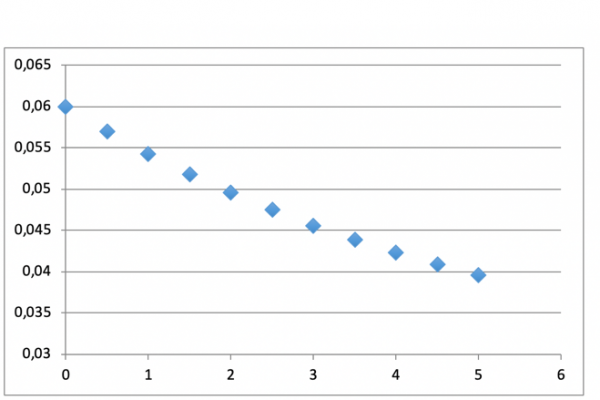

In the tests performed with stainless steel grade, the argon-oxygen mixture (10% vol.) Was insufflated to evaluate the decarburization obtained.

The expected chemical reaction is:

C + 1/2 O2 —> CO

the oxidation side reactions of the chromium and molybdenum elements are to be avoided.

Results of trials allowed to reach 0,03 % C level, however with some losses of Cr and Mo.

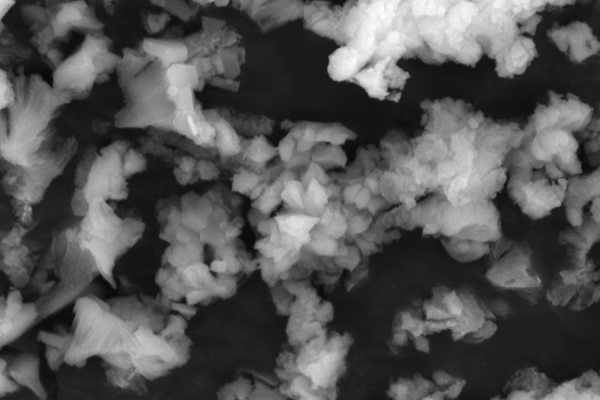

For carbon steel grade it was intended to inject reactive powders, particularly based on calcium compounds. Such powders should promote the formation of calcium aluminates, which are intended as liquids at 1600 ° C, so as to drag some of the dissolved sulfur and phosphorus into the bath. Both natural and commercial materials, as materials obtained from wastes, were tested.

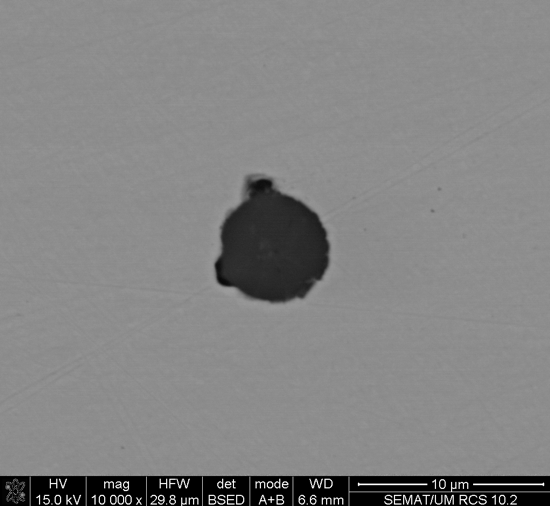

Results allowed to obtain globular calcium aluminates inclusions with relevant improvement of mechanical properties, especially those concerned at cryogenic temperatures.