The RCS – Refined Cast Steel has finished. With the obtained prototype and knowledge about decarburizing and dessulphurization/ dephosphorization ol liquid steels, by means of using additives made with industrial residues, Ferespe is now able to produce cast steels with even enhanced mechanical properties. With lower Carbon contents in the case of stainless steels, being […]

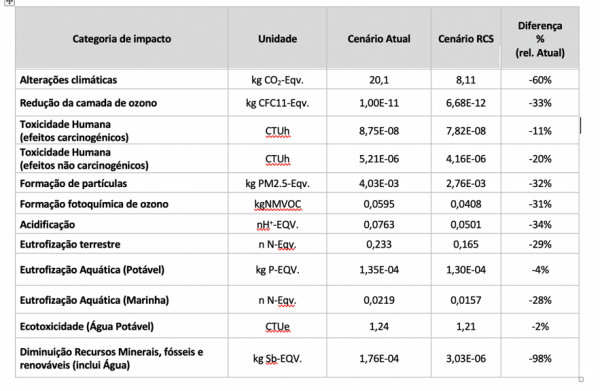

Environmental analysis of the process

Life Cycle Analysis of the process, where chemical compounds and materials are replaced by industrial wastes, has been done. The impact factors have been evaluated giving the following results, showing a strong reduction in some of them, highlighting the clear environmental benefits associated with the process.

RCS Project present in Wastes 2017 Conference

Some results of the project have been presented in the International Conference Wastes 2017, held in Porto, 25th and 26th September. This gave a publication in the book of selected proceedings F.A. Castro; J. Santos; P. Lacerda; R. Pacheco; T. Teixeira; A. Silva; E. Soares; J. Machado e M. Abreu – Employment of industrial wastes […]

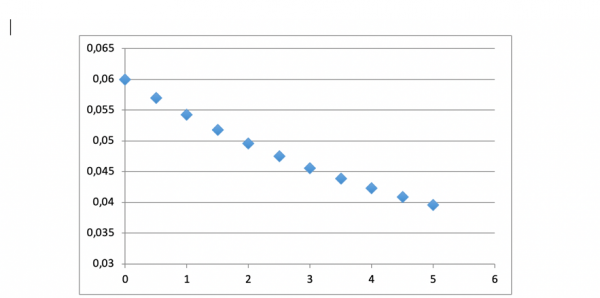

Decarburization of stainless steel tests running

During the project, and starting in December 2016, several tests were performed with injection of an argon-oxygen mixture with 8% by volume of this last gas. The intended reaction is: C + ½ O2 —> CO Whose chemical equilibrium constant is expressed by K = P CO / (a C x P O2 1 / […]

First injection tests being done

The first injection tests with the injection prototype have been done. They allowed to verify operating systems and suitability to run experimental test, both for the injection of gases as for solid powders. Following photos show some of the operations.

Injection system developed

The purpose of the system is to inject gases – either alone or in conjunction with reactive powders – into a liquid steel furnace to promote the modification of inclusions or carbon oxidation of the steel. The system must be capable of reliably and repeatably inflating to both the system itself and adjacent employees. It […]

Laboratory trials defined conditions for liquid steel treatment

This activity consisted of laboratory tests of steel production, with a view to the elaboration of low carbon stainless steels (decarburized) and low S and / or P carbon steels (desulfurized and / or dephosphorated). The decarburization and desulfurization / dephosphorisation processes were tested by reagent addition systems (argon / oxygen in the case of […]

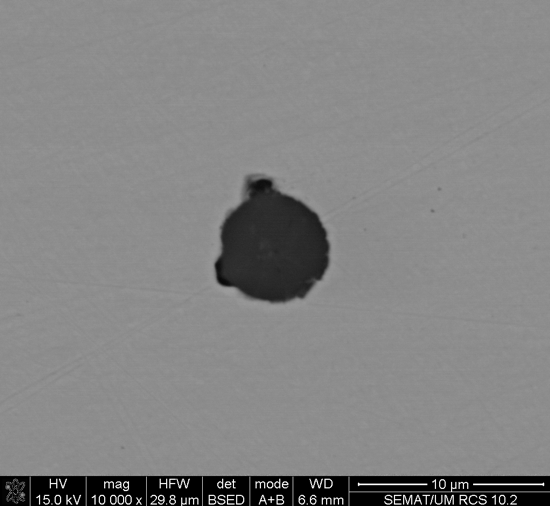

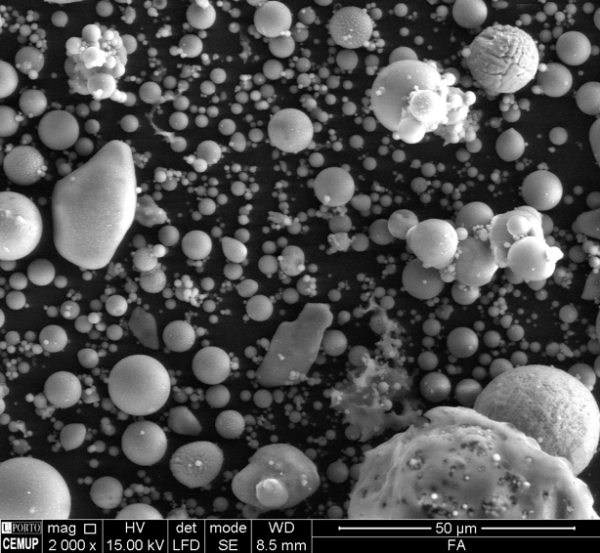

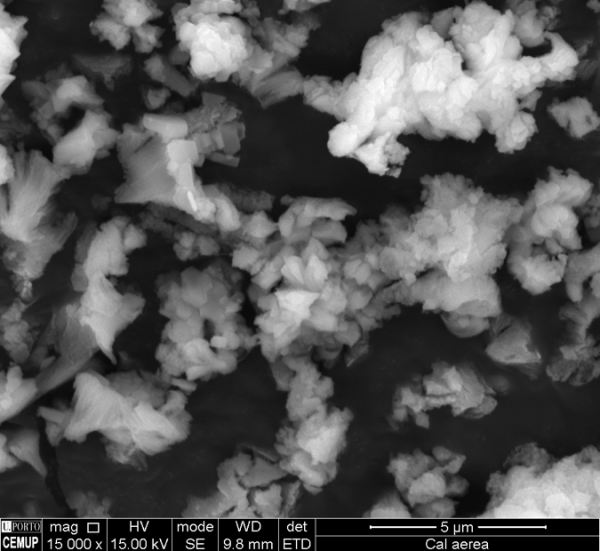

Characterization of wastes

Activity 2, Identification and characterization of wastes, is complete. Residues of potential interest for the production of additives that promote the desulfurization and dephosphorization reactions of liquid steel were identified and characterized. These are residues that primarily contain the elements calcium, aluminum and silicon and which, combined in certain proportions, can enhance the manufacture of […]

Activity 1 finished

The first activity of the project, Characterization of available raw-materials, has been completed, with the full characterization of the raw materials, both metallic scraps and potencial chemical for additives for liquid steel treatment. The procedures used were essentially of chemical analysis determination, aiming at the precise determination of the chemical composition of the materials. For […]